Home > > Products

Electro-Stop Monolithic Isolation Fittings

Innovative Engineering for corrosion protection

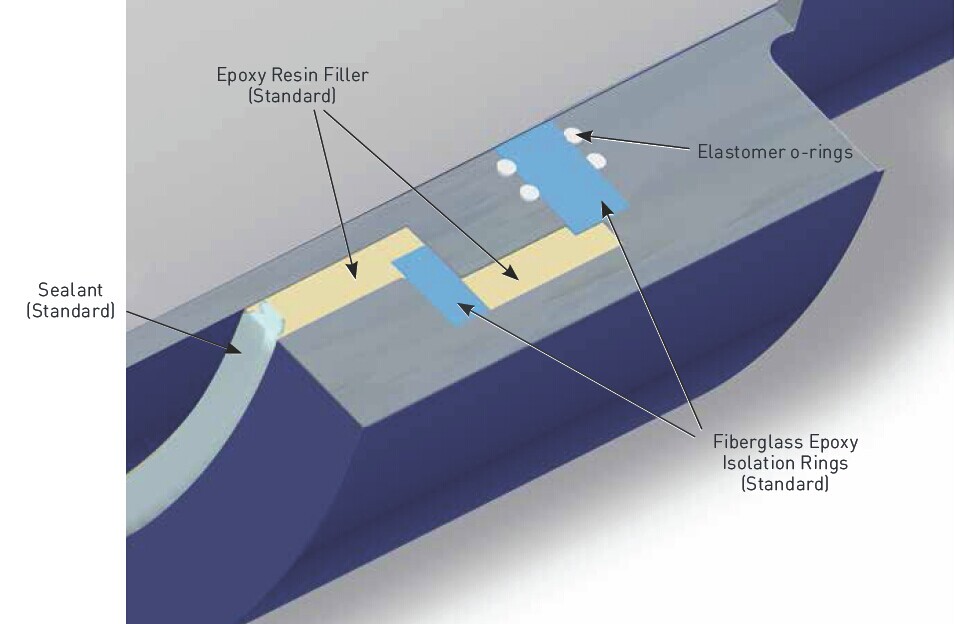

The Industry’s Dual O-Ring Seal

The Industry’s Dual O-Ring Seal

The Electro-Stop® monolithic isolation fittings manufactured by GPT in Houston, TX will serve as a positive, leak-proof, block against the flow of electric current in all piping systems. When you bury the Electro-Stop® isolation fitting you bury maintenance costs forever - an especially important feature for system operators and engineers.

Eliminates Short Circuits

Bolts, sleeves and washers - the major source of short circuits in most isolation assemblies - are eliminated with the Electro-Stop® isolation

fitting. Each joint is 100% electrically tested during production.

Eliminates Field Assembly

The Electro-Stop® isolation fitting is completely factory assembled and tested. There are no flanges, gaskets, nuts, bolts, sleeves or washers to handle and consequently no fluid leaks due to improper field assembly.

Is Less Expensive

Purchase the Electro-Stop® isolation fitting for less than the cost of the component parts of insulated flange assemblies in most pipe sizes. Install the Electro-Stop® isolation fitting for less than the labor costs of installing an insulated flange assembly.

Is Coated Both Internally and Externally

A thermally fusion bonded epoxy is sprayed to a thickness of .016-.024” (.40 to .60mm) to within 2” (50.8mm) of each weld end. Each joint is electronically tested for coating thickness.

Is 100% Hydrostatically Tested

All Electro-Stop® fittings undergo hydrostatic and cyclic pressure tests at 1.5 times rated operating pressure in accordance with the latest ANSI standards. Testing is normally conducted for 30 minutes for joints up to 6” and 60 minutes for 8” to 24” joints but can be tested per customer specifications. A pneumatic test is held at 87 psi for 10 minutes.

A pneumatic and hydrostatic test report is available upon request.

Is Completely Weld InspectedAll Electro-Stop® fittings undergo a weld inspection with combinations of ultrasonic (UT) and magnetic partical (MT) on all welds. In addition, X-ray tests can be conducted upon request. Manufactured In Accordance With ISO 9001:2008 Quality Assurance Control over all stages of production. Close

adherence to an in-place and on going ISO 9001:2008 quality assurance program which is constantly monitored and subject to periodic audit.

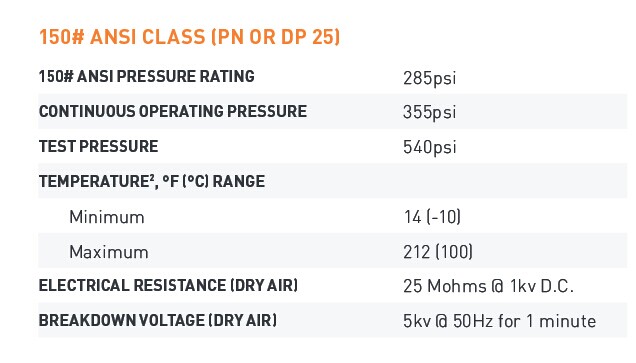

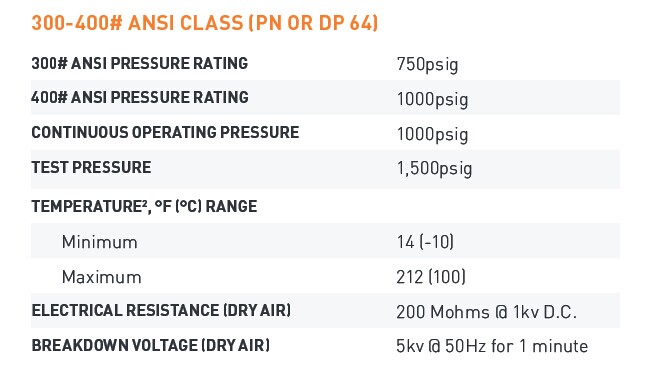

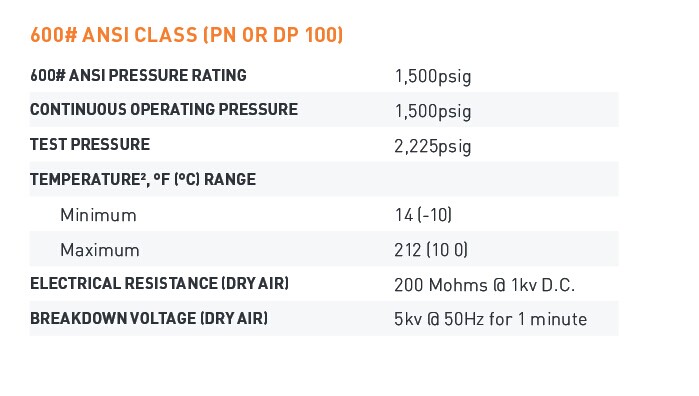

Monolithic isolation fitting specification

Monolithic isolation fittings shall be bolt less and completely factory assembled in accordance with the appropriate requirements of ASTM, API, DIN and BS codes. All welds shall be butt weld construction. The dielectric isolation material shall be a thermosetting fiberglass epoxy material. Sealing shall be by dual static, self energized “O” ring seals housed in accurately machined grooves, fully protected from cavitation in full compliance with ASME design codes. Interior and exterior coating shall be a two part epoxy with a thickness of .016 to .024” (.40-.60mm) to within 2” of each end. Each unit shall be tested for Electrical (@5kv, 25 Mohm), Hydrostatic (@ 1.5 x O.P.) and Weld (Ultrasonic/Magnetic Particle). The Monolithic Isolation Fitting shall be the Electro-Stop® Isolation Fitting as manufactured by GPT.

QUALITY ASSURANCE

Each monolithic isolation fitting shall be manufactured at a facility that has a Registered ISO 9001:2008 Quality Management System. Copy of current ISO 9001:2008 Registration shall be provided with material submittal.

| ADD: Room 918,Block A, Wanda Square, Tongzhou District ,Beijing, China |

| TEL:+86 010-60563990 |

| FAX: +86 010-89503120 |

| Code: 101100 |

| E-mail: jessie@wyxbj.com |